Polyester acoustic panel is made of 100% polyester fiber and has the characteristics of sound absorption, heat preservation, flame retardant, environmental protection, light weight, easy processing, impact resistance, etc. It is a new product developed to replace glass fiber and asbestos fiber.

① It is close to nature and harmless to human body;

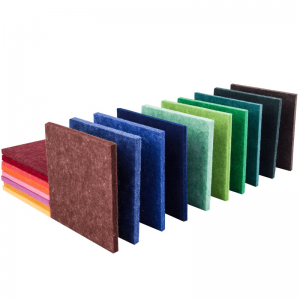

② Rich colors and patterns, there are more than 40 kinds of colors, which can be directly used as decorative materials, or can be sprayed with various types of paints on the surface;

③ It is highly decorative and easy to construct. It can be transformed into a variety of shapes through simple woodworking tools, which can directly replace the traditional soft-packing process of lamination plus sponge or glass fiber. Therefore, polyester acoustic panel has become the preferred decorative sound-absorbing material for interior decoration.

Construction method of polyester acoustic panel

1.Panel selection and layout:

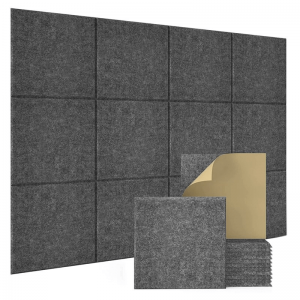

Pay attention to the color difference, find the center point of the sticking surface, draw a cross line, and use the method of laying bricks to start the layout from the center point (it is best to wear gloves to avoid pollution).

2.Cutting the board surface:

Use a steel ruler and a sharp utility knife to cut or modify it accordingly. If it is more beautiful, the blade can be tilted inward by 0.5-1mm during cutting, which is convenient for the edge of the board to connect and reduce the gap.

3. Paste:

①Cement or wood base: You can choose benzene-free all-purpose glue or white latex with neoprene as raw material.

②The base surface of the gypsum board: under the premise that it is not easy to be affected by moisture, white latex or cellulose-based wallpaper glue can be used (after brushing and pasting, it should be fixed with nails immediately to avoid the glue is not dry and the board surface moves ). Under the premise that it is easy or possible to get wet, use all-purpose glue to ensure the quality.

③ Polyester acoustic panel is a porous material, which is easy to absorb glue, block holes, and affect the sound-absorbing function of the rear cavity. Therefore, during construction, it can be brushed with glue on one side, that is, only on the base plate or keel, and the amount of glue is slightly more than normal. At the same time, it can also be fixed with nails.

Cleaning problems after construction of polyester acoustic panel

There are mainly three kinds of stains encountered in the construction of polyester acoustic panel:

① Mud stains. Wet the polyester fiber board with clean water, and scrub it with a scrubbing material with a high water absorption rate and a weak alkaline foam cleaning agent.

② Ash and dust. Simply vacuum the surface with a vacuum cleaner.

③ Oil stains and rust stains. This is a more difficult stain to remove. It should be cleaned with special degreasing and rust remover, or it can be used for automobiles.

Post time: Sep-08-2022